Sustainability in Manufacturing

In the ever-evolving realm of modern manufacturing, sustainability has surged to the forefront, becoming an indispensable thread woven into the fabric of production methodologies. Enter AP Precision—a company that doesn’t just dip its toes into eco-conscious waters but dives headfirst, embracing a kaleidoscope of innovative techniques designed to slash waste and curtail environmental footprints. Picture this: recycling aluminum busbars with finesse while rolling out cutting-edge energy-efficient technologies—these are not mere buzzwords here; they’re a way of life.

But wait! The commitment to sustainability doesn’t stop at the factory gates. No, indeed! AP Precision forges alliances with suppliers who hold themselves to lofty responsible sourcing standards. This is no haphazard approach; it’s a meticulously crafted strategy ensuring that each phase of production—from acquiring raw materials through to delivering those final products—echoes an unwavering dedication to eco-friendly principles.

By placing sustainability squarely on its pedestal, AP Precision cements its stature as a trailblazer in the aluminum busbars market, simultaneously captivating clients who are increasingly attuned to ecological stewardship and responsibility. A dance between innovation and conscience unfolds here—a testament not merely to efficiency but also to an ethical compass guiding every decision made along the way.

Environmentally Friendly Practices

At AP Precision, the dedication to sustainable manufacturing runs deep, a fervent commitment that seeks to minimize environmental footprints in every conceivable way. With cutting-edge technologies and a treasure trove of eco-friendly materials at their disposal, this company doesn’t just produce – they innovate energy-efficient methodologies that redefine production norms. Waste isn’t merely managed; it’s meticulously reduced through astute oversight and robust recycling initiatives. This all-encompassing strategy transcends mere compliance with industry standards; it boldly establishes a gold standard for those wandering in the realm of aluminum busbar manufacturing.

But that’s not all! Delving into sustainable sourcing practices ensures raw materials are harvested with responsibility etched into their very essence. By forging alliances with suppliers who resonate on the same frequency of environmental stewardship, AP Precision amplifies the sustainability quotient of its offerings. The implementation of rigorous quality control measures guarantees these noble practices harmonize seamlessly with the company’s lofty ecological aspirations. In this intricate dance between operational efficiency and eco-consciousness, AP Precision emerges as both an innovator and a guardian of our planet’s future.

Competitive Pricing Strategies

AP Precision crafts a pricing strategy that dances between cost-effectiveness and unwavering quality standards, a delicate balance akin to walking a tightrope. Harnessing cutting-edge manufacturing technologies and fine-tuning production processes, the company masterfully slashes waste and trims operational costs. This savvy efficiency opens the door to competitive prices for clients—without ever compromising the integrity of their final product.

Customers revel in stable pricing that resonates with both those counting every penny and those on the hunt for top-tier aluminum busbars. But there’s more; AP Precision champions transparency in its pricing structure, nurturing trust and cultivating long-lasting relationships with its clientele. With an astute eye on market dynamics, the company deftly adjusts its prices to mirror shifts in material costs and demand fluctuations.

By persistently reassessing its pricing strategies, AP Precision ensures that it remains accessible across a broad spectrum of industries—all while steadfastly upholding its pledge to quality and performance excellence.

Cost-Effectiveness Without Compromising Quality

AP Precision has carved out its niche as a frontrunner in the realm of aluminum busbar manufacturing, deftly juggling cost-effectiveness while steadfastly upholding uncompromising quality. With a keen eye for innovation, the company pours resources into cutting-edge manufacturing technologies and streamlined production processes that work in harmony to minimize waste and trim operational costs like excess fat from a well-prepared steak. This strategic dance allows AP Precision to present competitive pricing without skimping on excellence—each product screams high performance and enduring durability.

A robust commitment to quality assurance pulsates through every phase of production. Stringent testing protocols coupled with unwavering adherence to industry standards ensure that each busbar not only meets but often surpasses customer expectations—a feat akin to hitting a bullseye repeatedly at an archery contest. This relentless dedication doesn’t just solidify client trust; it elevates the company’s standing in a marketplace where reliability and affordability reign supreme. Clients reap the benefits of products designed for long-term efficiency, delivering exceptional value wrapped neatly without compromising on quality—a win-win scenario if there ever was one!

Customer Testimonials

Clients often rave about the rock-solid reliability and remarkable efficiency of AP Precision’s aluminum busbars, weaving them into the very fabric of their operations. Feedback flows in, highlighting not just durability but a performance level that stands tall even in the most demanding environments. It’s not merely about the quality of these busbars; customers are equally impressed by the stellar customer service they experience throughout their purchasing journey. This exceptional support has nurtured enduring relationships between AP Precision and its clientele, cementing a robust trust in the brand.

A plethora of businesses have stepped forward to share success stories that vividly showcase how AP Precision’s aluminum busbars can revolutionize operations. One manufacturing plant reported slashing maintenance costs after transitioning to these cutting-edge components, paving the way for boosted uptime and productivity—a game changer! Meanwhile, another client from the renewable energy arena extolled how these busbars enhanced energy efficiency within their systems. These glowing testimonials paint a picture of a company fiercely dedicated to not just meeting but surpassing its customers’ expectations amid fierce competition in today’s marketplace.

Success Stories from Satisfied Clients

AP Precision has carved out a stellar reputation for itself, and it all boils down to one thing: an unwavering dedication to customer satisfaction. Picture this—a leading electrical contractor recounts their experience with AP Precision aluminum busbars in a massive commercial venture. They couldn’t help but rave about the reliability and efficiency of these busbars, emphasizing how the installation process unfolded like clockwork, significantly boosting the electrical systems’ overall performance. The project wrapped up ahead of schedule, yielding impressive cost savings and leaving a delighted client in its wake.

Then there’s another thrilled client—the international renewable energy firm—who can’t stop singing praises for the innovative designs and versatility offered by AP Precision’s products. Their customized aluminum busbars proved indispensable in tackling the unique challenges posed by solar energy installations. Feedback from their engineering team painted a clear picture: they witnessed a notable uptick in energy distribution efficiency! This fruitful collaboration didn’t just enhance operational outcomes; it also solidified what promises to be a long-lasting partnership with AP Precision.

| Client Name | Industry | Product Used | Feedback | Outcome |

|---|---|---|---|---|

| Leading Electrical Contractor | Commercial | Aluminum Busbars | Highly reliable and efficient installation process | Project completed ahead of schedule with cost savings |

| International Renewable Energy Firm | Renewable Energy | Customized Aluminum Busbars | Innovative designs helped tackle unique challenges | Improved energy distribution efficiency and established a long-lasting partnership |

| Local Industrial Facility | Manufacturing | Aluminum Busbars | Exceptional versatility for complex installations | Enhanced productivity and operational reliability |

Industry Applications of AP Precision Busbars

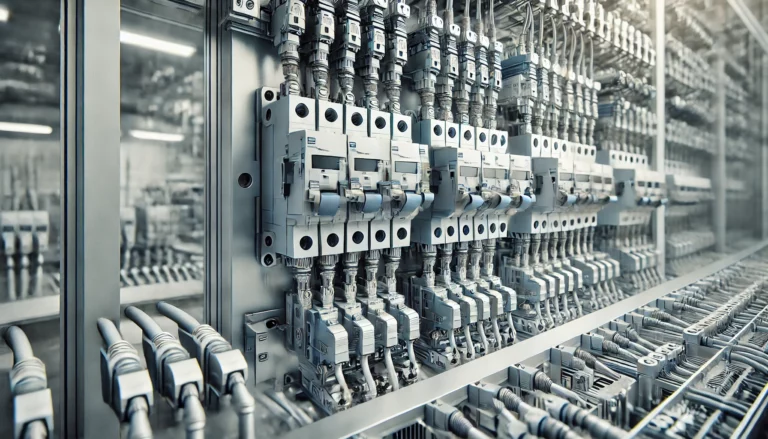

Aluminum busbars from AP Precision weave their way through a myriad of industries, capturing attention with their featherweight design and remarkable electrical conductivity. These unassuming components play pivotal roles in realms like renewable energy, automotive innovation, and power distribution. In the vibrant world of renewable energy systems, busbars become the lifelines that efficiently transport electricity generated by solar panels and wind turbines—fueling the momentum behind sustainable energy initiatives that promise a greener future. Meanwhile, in the fast-paced automotive sector, they emerge as key players in crafting electric vehicles; enhancing power management systems while enabling groundbreaking vehicle designs.

But don’t let their specialized applications fool you! Beyond these headline markets, AP Precision’s busbars find themselves at home in commercial construction projects, bustling data centers, and dynamic industrial manufacturing environments. Their capacity to handle hefty current loads without breaking a sweat establishes them as indispensable for reliable power distribution within sprawling buildings and facilities. As AP Precision forges ahead into uncharted territories of innovation, they remain steadfastly committed to refining their products—ensuring each busbar not only meets but exceeds rigorous safety and efficiency standards demanded by an ever-evolving landscape.

Versatility Across Various Sectors

Aluminum busbars—oh, what a fascinating intersection of engineering and efficiency! These pivotal components weave through diverse realms like renewable energy, telecommunications, and the sprawling expanses of commercial construction. Their lightweight charm coupled with stellar conductivity renders them nothing short of indispensable for applications where both reliability and performance reign supreme.

Take the renewable energy sector: here, busbars serve as sleek lifelines connecting solar panels and wind turbines to inverters, orchestrating a symphony of optimal power distribution that dances across grids. In the bustling world of telecommunications, these unassuming heroes prop up the very infrastructure vital for smooth data transmission—a testament to their crucial function in driving technological advancements forward!

Meanwhile, within the vibrant tapestry of commercial construction, aluminum busbars flaunt their versatility like a well-tailored suit at an upscale gathering. They offer flexible configurations that mold effortlessly to various building designs—a chameleon-like adaptability! Plus, let’s not forget their impressive resistance to corrosion; even in harsh environments where others might falter, these stalwarts endure. This durability translates into longevity while slashing maintenance costs—a win-win!

And oh—the customization possibilities! Manufacturers eagerly craft bespoke busbar solutions tailored to meet specific needs—each configuration an answer to unique challenges posed by clients across industries. It’s all about enhancing operational effectiveness in this dynamic landscape where every detail counts!

- Aluminum busbars provide high electrical conductivity, essential for efficient energy transfer.

- Their lightweight nature makes installation and handling easier in various settings.

- Outstanding resistance to corrosion ensures reliable performance in challenging environments.

- Custom configurations allow for tailored solutions, enhancing flexibility in design.

- Reducing maintenance costs through durability contributes to overall operational savings.

- Their role in power distribution is vital for the functionality of renewable energy systems.

- Busbars enhance the reliability of telecommunications infrastructure, supporting data and voice transmission.

Future Trends in Aluminum Busbar Technology

The aluminum busbar technology market is undergoing a remarkable transformation, one that buzzes with the promise of heightened efficiency and performance. As the appetite for renewable energy solutions surges, manufacturers are diving headfirst into innovative designs and cutting-edge materials—think improved conductivity paired with minimized energy losses. This metamorphosis seeks to satisfy the escalating demands of sectors such as electric vehicles and renewable energy systems, which crave power distribution components that are not just reliable but exceptionally efficient.

But wait—there’s more! The rise of smart technologies is carving out an essential niche in busbar design. By weaving in sensors and IoT connectivity, we’re ushering in an era where real-time monitoring of electrical systems becomes a reality. This leap forward not only catapults operational efficiency to new heights but also paves the way for predictive maintenance strategies that can save time and resources. Such technological strides don’t merely enhance resource management; they also align beautifully with sustainability objectives across various industries. With these exciting developments on the horizon, aluminum busbars are poised to be pivotal players in shaping the future landscape of power distribution and energy management!

Anticipating Changes in Market Demand

Grasping the nuances of market trends is absolutely crucial for players in the aluminum busbar arena. As the spotlight intensifies on renewable energy and electrification, an insatiable appetite for efficient and dependable electrical solutions has emerged. Enter AP Precision—this company doesn’t just watch; it vigilantly tracks every twist and turn in technology and consumer desires, deftly adjusting its product lineup while sparking innovation to keep pace with the ever-shifting landscape.

Consider the meteoric rise of electric vehicles coupled with the proliferation of smart grid technologies—these phenomena underscore an urgent need for top-notch busbars. AP Precision stands resolute, pouring resources into research and development like a craftsman honing his finest tools, ensuring that its offerings not only meet but exceed industry standards across diverse sectors. By remaining at the forefront of these dynamic trends, AP Precision aspires not merely to bolster its competitive advantage but also to play a significant role in crafting a sustainable future within electrical manufacturing.

Conclusion

AP Precision stands as a beacon of excellence in the realm of aluminum busbar manufacturing, driven by an unwavering dedication to sustainability, inventive practices, and customer satisfaction. Picture this: their eco-friendly production methods harmoniously intertwine with competitive pricing, opening doors across diverse industries while upholding rigorous standards of quality and performance. This isn’t just a business model; it’s a testament to their position as market leaders—a badge they wear proudly—while simultaneously embracing the mantle of responsibility for sustainable development.

Now, let’s gaze into the crystal ball of aluminum busbar technology’s future—it’s dazzling! AP Precision is not merely riding the wave; they’re creating it with anticipated innovations that promise to reshape the landscape. With an eye on versatility and adaptability, this company is poised like a seasoned surfer ready to tackle ever-changing market demands head-on. Their cutting-edge solutions are tailor-made for clients who crave excellence. Such visionary strategies don’t just ensure survival; they set lofty benchmarks within the industry where others will aspire to follow!